Inventory Management System Capstone Project Document

Introduction

Inventory management is the process of efficiently monitoring the constant flow of units into and out of an existing inventory. This process usually involves controlling the transfer in of units in order to prevent the inventory from becoming too high, or dwindling to levels that could put the operation of the company into difficulties. Inventory management is very important for big business and private owned organizations especially where there are a lot of orders are being placed everyday and there are lot of materials and the maintenance is really important which the system will do and also will record the time taken to process an order and this system is really important as it can help the organizations to be alerted when the level of inventory is very low .and focuses on the three aspects of inventory management and prevent from failures in the future .

Inventory management also demands a solid understanding of how long it will take for those materials to transfer out of the inventory to be established. By Knowing these two important lead key aspects makes it possible to know when to place an order and how many units must be ordered to keep production running smoothly.

The two common inventory-management strategies are the just-in-time method, where the companies plan to receive items as they are needed rather than maintaining high inventory levels, and materials requirement planning strategy, which schedules material deliveries based on sales forecasts. Inventory management forms a part of the project management.

Background of the Company

Organization Review

Hashem Contracting and Trading Co was established on 25 March 1979 and the company has 3 owners namely Mr. Ghiath Eldin Mehdi Kabbani ,Mr. Suleiman Saleh Al-Rajhi and Mr. Abdul Rehman Ghiath Eldin Kabbani Hashem Contracting invests in real estate development projects including residential, commercial and mixed-use real estate projects through its real estate division. It also engages in the planning of development projects in collaboration with other partners and in the implementation stage through contracting and finance.

As a general contractor, Hashem Company provides the following turnkey services:

Civil works

- Structural works

- Architectural works

- Mechanical work HVAC

- Plumbing works

- Electrical works

- Special works Subcontracting

- Fire Fighting

- Landscaping

- Specialized works

- Other value addition services

Hashem Aluminum Systems Factory

- Aluminum products ( Doors, Windows, Facade Cladding )

- Skylight

Projects & Furnishing

A sister company for wood works

Problem Statement

The process of manually looking for the inventory available in stock is really time consuming and cumbersome that includes the person responsible to see how many materials are in the inventory , how many materials have been ordered and received and keep the record of the time that will take for the suppliers to process orders and other various tasks included in inventory .

At current the inventory is managed and update on an excel spreadsheet which has been an outdated form of recording and maintain the inventory of materials as it is really difficult to enter the data and then update the data on daily basis .the inventory management system will solve the problems as everything about the inventory will be stored in a database which will be much easier to marinating and update and this will also save time and cost effective for the organization and will automate many inventory related tasks.

The project will implement a database for inventory management which will include the vendor analysis performance of the products and calculate the cost of materials at the end of the project .Online inventory management system will provide all the information needed and required for inventory related in understanding in easy way and that will reduce the time taken for the inventory manager to record all the products that are in inventory which takes too much time. This will help the inventory manager to list out all the details using the system or search all the inventory information.

Research Scope

The aim of the research is to develop a web based inventory management system that will be implemented within the company to help the inventory manager record the details of the inventory and the details of the inventory including the product ,supplier ,order and all information shall be stored in the database .the system will provide all of the information needed for inventory manager ,display the product information ,the supplier info which will enable the inventory manager to create /delete inventory or add new inventory or send alerts when the inventory levels are low in stock and will enable to track order history of vendor.

The research covers the planning, analyzing and designing phases of the system. A prototype is also created to describe how to use the system. Implementation and testing is also included in this research.

Research Objectives

This section illustrates the three types of objectives general, specific and the learning objectives that are required in order to complete this project.

General Objectives

The following points are considered the general objective of the research

- Conduct and research the real life workflow and be able to understand and identify real life and business problems.

- To propose a solution to the problems identified.

- Analyze and design a solution that fulfills the client’s needs .

Specific objectives

The research will help to cover the following objectives

- Understand the company Hashem construction and trading current way of inventory tracking.

- Identify the problems.

- Identify the type of system that would help solving the problem.

- Study and search about similar systems.

- Similar soft wares that is used to help in solving the problems.

- Understand and specify the requirements of the system.

- To specify the tools needed to build the system and how to use them. Design the architecture and the interfaces for the proposed system Implement a functional system and the test the system.

Learning Objectives

After doing the literature review and conducting the research about the system, there are some expected deliverables on these following topics:

- Understand what the task management system are , how they work ,and their importance in today’s business world.

- Identify the data, processes and knowledge involved in the problem.

- Prepare system requirements analysis.

- Learn how to design and implement a system into real life workflow.

Research Methodology.

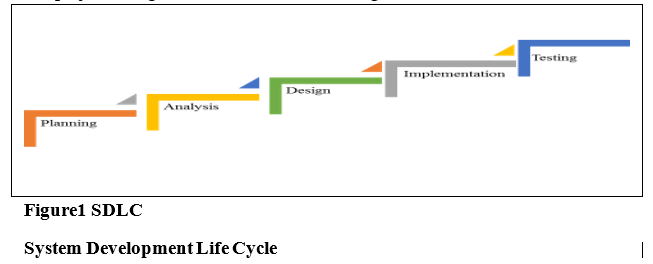

This section identifies the steps that were followed to achieve the goal of this research. The methodology that I have chosen and intend to use for this project is the Systems development life cycle .This methodology is chosen because it has all the steps that will be followed that must be performed for the development of a successful and better system .This project based on the SDLC methodology will reduce errors and produce better results at the end of the project. The system development life cycle (SDLC) categorizes the development of any system into the following: planning, analysis, design, implementation and testing. This is the division that will be followed throughout this project as Figure1 shows the five main stages in an SDLC.

The common stages are :

Project planning , feasibility study: In this phase the team establishes a high level view of the project and specify its goals.

System analysis: System analysis emphasizes on the identifying the problem . It is the process of examining and existing information system and its environment to identify possible environment .There are further sub steps in the analysis phase and they are :

- Prepare for system analysis.

- Determine business requirements.

- Define process models.

- Define logical data.

- Reconcile business requirements with models.

- Gather and produce functional requirements. Produce the nonfunctional requirements.

System Design:

This phase emphasizes on the technical or implementation concerns of the system .and also includes identify alternative solutions and chose the best .Then design the chosen solution. The specification of a computer based solution also called physical design .There are further steps involved in the design phase and they are :

- Prepare for system design.

- Define the technical architecture.

- Define system standards.

- Create the physical database.

- Prototype system components.

- Produce technical specification.

System Implementation

This phase includes the coding and the implementing the system for the use of the client.

System Testing

The team will test the system and checks for error, bugs and interoperability.

Acceptance, installation and deployment : This is the final stage of initial development.

Maintenance:

What happens through system entire life , the changes ,correction, addition, move to a different computing platform or say migration and porting and more. This is the least valuable perhaps the most important stage at all.

Required Tools

This section provides a brief description of the major software tools to be used in developing the application. This includes Microsoft SQL Server, Microsoft Visual studio and c#.

Microsoft SQL Server

Microsoft SQL Server is a relational database management system that uses the structured query language SQL to access and manipulate the stored data developed by Microsoft. It is software product whose primary function is to store and retrieve data as requested by software applications. Its scope includes data query and data update , schema creation and modification and data access control. In SQL server , the RDMS is integrated within the visual studio IDE to simplify data access from windows applications.

It can install the database in separate server with the same data and it can install it with the same server .The servers must be in the same network. Their version of the SQL based on the applications and the size of the business.

Microsoft Visual Studio

Visual studio is a software development or integrated development environments, it used to develop the graphical user interface and the console based on the windows form applications like the website, web services and web applications of all code for all platforms supported by Microsoft like windows mobile and Net framework (Microsoft Visual Studio ,N.D.) Features:

Visual studio can edit the code easily by the code editor. Also it has two levels , which are machine level and source level debugger. For the designing, it has many designers like Windows Form Designer, WPF designer and Web designer. Additionally visual studio supports other products.

C#

C# is an object oriented programming language from Microsoft that aims to combine the computing power of C ++ with the programming ease of Visual basic .C# contains features similar to those of Java. Its syntax is similar to C and C++ syntax and C# is designed to be an object oriented language (Hans-Petter Halvorsen, N.D).Services .

Features

- Variables in C# are automatically initialized by environment.

- Strong Exceptions Handling.

- Suited well for building Web services.

- The language is intended for use in developing software component suitable for deployment in distributed environments.

ASP.NET

ASP. NET(Active Server Pages ) is a web development framework that helps in creating dynamic pages and websites with HTML , CSS, JavaScript and Server scripting. It was developed by Microsoft to allow users to produce dynamics websites, web applications and web services.ASP.NET web pages are known as web forms , those are the main building black for application development. Web forms contained files with”.aspx” extension; these files contain HTML, user controls and web controls where developers place all the content for webpages .The dynamics code, which runs the code on the server ,can be placed in the page with a block. (ASP.NET , 2013).

ASP.NET key advantages are :

- It is built on .NET framework and it allows users to use any languages that supports .NET framework while creating applications.

- NET has the concept of code-behind ,which means code and HTML markups are separated Which make the code readable and easier for developer to maintain and update.

- It comes along with a comprehensive set of Web Controls (Button,

Data Grid).This helps developer to focus on business requirements.

- NET has built-in authentication and authorization tools that provide a developer with the ability to create highly secured applications.

- Support of Mode-View-Controller concept.

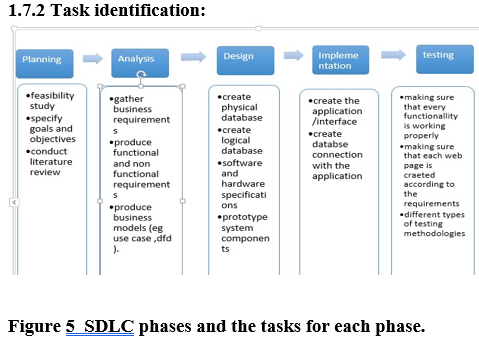

The tasks that were carried out during each phase are then illustrated in the diagram above.

And

The tasks that were carried out in each of the phases of system development life cycle are identified and explained as below:

The first stage in the system development life cycle is Planning and following were the tasks that were carried out in the Planning phase are as follows:

Planning Phase:

- Established the goals of the project.

- Identify some main objectives for the project and some general and research objectives that are used in all the projects.

- Identify the problem and also provide a solution as is written in the problem statement .This statement gives a general overview of how the problem would be solved.

- Identified some tasks and functionalities that would be carried out by the different users after implementing the application.

- Specify some user requirements for the different users which will later be explained in the system analysis phase of the system development life cycle.

System Analysis:

The second stage was the System analysis and following were the tasks that were carried out during this phase of the system development life cycle and are as follows:

- User requirements were defined that were categorized in to functional and non –functional requirements : These requirements specify the functionalities of the system by the different users and for the non- functional requirements the requirements are normally the same that would be applied in all the projects regarding the accuracy ,disaster recovery handling ,design of the application interface the GUI and all other requirements . Business requirements were also identified through the meeting with the client in the form of questionnaires.

The process models that were created in the analysis phase are explained as below :

- Use cases Diagrams : These diagrams were developed on the basis of the system functional requirements and the description of the use cases were also provided with the function of the actor with the use case and what the system will interact with the user and the function of the system in response to that particular use case.

- Data flow Diagram : This diagram was developed to show how the data is linked in between the different users of the system and what are the data sources if any from where the data will be needed for the databases.

- Functional Decomposition Diagram: This diagram was developed in order to establish the link between the different users and their common functionalities.

System Design Phase:

There were some tasks that were carried out in the system design phase that are explained as below:

- ER Diagram : This diagram was developed to tell how the different entities in the system are linked to each other entity with their attributes also listed.

- Data Dictionary: This dictionary is really important for the creation of database .Before the database creation it is really important to know how many tables will the database contain and with their primary keys and foreign keys specified for each table that would be created in the database.

- Physical Database :This database is the result of the actual creation of the database using the software SQL server. The tables are created to be used for the database and the SQL server database is linked to the visual studio database.

- System Environment : The hardware and the software specifications were then specified further as displayed in the tables.

- Sitemap : The sitemap was also developed as part of this phase to give an idea of how the application will look when implemented including how many main pages and how many sub web pages will be there in the application and how each sub web page is connected to the main home page of the system.

- Different prototypes of each webpage was then created to give the idea of the look of each page before implementing the system.

Implementation phase:

The last phase of the system development life cycle is the implementation and testing phase and following are the tasks that were carried out during this phase and are described as follows:

- Review of the changes in requirements : There were some requirements that were reviewed and changed after getting the feedback from senior1.

- ERD was updated : This was updated as part of the changes in requirements from the senior 1 part of the project .

- Development of the project : How the project will actually progress further .This listed out some of the tasks to be carried out in the implementation phase .

- Selection of tools : The tools and softwares specifications and the hardware specification that were used in developing the application was then displayed .

- Screenshots of the application and the screenshots of each of the web page that was created was also included as part of this phase.

Testing phase:

The tasks that was carried out in the final stage of the system development life cycle is explained as below:

Three different types of testing methodology that was used for implementing the application and are as follows:

- Unit testing: after coding in the implementation phase, a unit test was performed upon on the code.

- User acceptance testing: was performed by the client to check that the application meet the requirements.

- System Integration Testing: making sure that all different webpages of the application is well able to communicate with each other.

Following were the different tables that were included in this phase which are as follows:

- Mapping system requirements to use cases :Use cases were then mapped to the system requirements (functional requirements).

- Mapping scenarios to use cases: Some scenarios were provided and these were then mapped to the use cases.

- Test scenarios and test cases: Test scenarios were provided and some test cases were provided with the result of applying the test cases.

Literature Review

- Components of Inventory management systems

The Inventory Software is the base with components like Barcode or RFID scanner, Barcode or RFID label printer. There is Retail Inventory System, stockroom inventory, warehouse Inventory System, and fixed asset inventory. For the most efficient Inventory System should be integrated with the rest of your operations like sales, shipping and receiving, accounting, and billing. You still can isolate the inventory tracking if that is critical to your operation.

- A barcode reader (or barcode scanner) is an electronic device for reading printed barcodes. Like a flatbed scanner, it consists of a light source, a lens and a light sensor translating optical impulses into electrical ones.

Additionally, nearly all barcode readers contain decoder circuitry analyzing the barcode’s image data provided by the sensor and sending the barcode’s content to the scanner’s output port.

- Radio-frequency identification (RFID) is the wireless non-contact use of radio-frequency electromagnetic fields to transfer data, for the purposes of automatically identifying and tracking tags attached to objects. The tags contain electronically stored information. Unlike a barcode, the tag does not necessarily need to be within line of sight of the reader, and may be embedded in the tracked object.

Inventory management is made up of several key components that work together to create a cohesive inventory for inventory organizations .These features include:

- Order management: This helps to decide should inventory reach a certain threshold, a company’s inventory management system can be programmed to tell managers to reorder that product. This helps companies avoid running out of products or tying up too much capital in inventory .

- Asset tracking

When a product is in warehouse or stock , it can be tracked via barcode or any RFID or any other tracking criteria such as serial number, lot number or revision number. Nowadays most companies uses the barcode or RFID technology or other wireless technology for tracking the products.

- Service management

Companies that are primarily service oriented other than product oriented uses the inventory management software to calculate the cost of materials that is used to provide services such as cleaning supplies.

- Product identification

Barcodes are the often used means to whereby the data on the products and the orders is inputted in the inventory management software. A barcode reader is used to read barcodes and look up information on the products they represent. Radio-frequency identification (RFID) tags and wireless methods of product identification are also becoming more popular.

- Principles of inventory management systems

- Demand forecasting

- Warehouse flow

- Inventory turns/stock rotation

- Cycle counting and

- Process auditing

- Demand forecasting: This depends on the industry, inventory ranks in the top five business costs. Accurate demand forecasting has the highest potential savings for any of the principles of inventory management. Both over supply and under supply of inventory can have critical business costs. Whether it is end-item stocking or raw component sourcing, the more accurate the forecast can be.

Establishing appropriate max-min management at the unique inventory line level, based on lead times and safety stock level help ensure that you obtain when you need it. This also avoids costly overstocks. Idle inventory increases incremental costs due to handling and lost storage space for fast-movers.

- Warehouse flow: the old concept of the warehouse being dirty and in unorganized form is outdated and costly. Lean concepts including the S5 have found way in warehouse. Sorting , setting order, systematic leaning and ensuring discipline makes sure that money is worth spent in all these processes.

The principles of any inventory management are not different form other system. Each process from housekeeping to inventory transactions requires a proper, formal standardized process to ensure correct results.

Inventory Turns/Stock Rotation

In certain industries, such as pharmaceuticals, foodstuffs and even in chemical warehousing, managing inventory can be critical especially to minimize business costs. Inventory turns is one of the key metrics used in evaluating how effective your execution is of the principles of inventory management.

Defining the success level for stock rotation is critical to analyzing your demand forecasting and warehouse flow.

- 4Cycle counting

One of the accurate methods of maintaining accurate inventory is cycle counting. This helps measure success of your existing processes and maintain accountability for potential error success. Some industries require 100% periodic counts .this can be achieved through perpetual inventory maintenance or full building counts.

Process auditing

Proactive source error identification starts with process auditing .One of the most important principles of inventory management is to process auditing which should be done often .Process auditing should take place at every transactional steps from receiving and to shipping inventory including all the inventory transactions that takes place in between the processes.

Advantages of inventory management system

The some of the advantages of inventory system are thus summarized below which can prevent the organization /firm from suffering from big financial loss and other problems that may occur during the daily operations of the firm that can be viewed as the materials being out of stock or machine failures and many other operations happening on daily basis.

There are several Advantages of using the inventory management in a business setting are :

- Cost savings: In many cases companies inventory is one of the largest investments along with its workforce and locations. inventory management systems helps the companies to cut the expenses by minimizing the amount of unnecessary products and materials in storage.it also helps companies keep lost sales to a minimum by having enough stock to meet demand .

- Increased efficiency: the inventory management system allows for may automated inventory task for example the system can automatically collect data , calculate costs .this also reduces in costs saving and time saving and thus consequently leading to increase in business efficiency.

- Warehouse organization: Inventory management system help distributors, wholesalers, manufacturers and retailers optimize their warehouses. If certain products are often sold together or are more popular than others, those products can be grouped together or placed near the delivery area to speed up the process of picking.

- Updated data: provides up to date and real time data on inventory levels is and advantage of inventory management system. Company executives can usually access the software through their mobile devices , laptop for checking current inventory numbers this automatic updating of inventory allows the business to make informed decisions.

- Data security : by accompanying with the restricted user rights, company managers can allow many employees to assist in inventory management. They can grant employees enough information access for tasks such as receiving products, making orders, transfer products and perform other tasks without compromising company security. This can speed up the inventory management process and save managers’ time.

- Insight into trends this helps tracking the products which are in stock and from which suppliers do they come from and the length of the time they are stored is made possible with inventory management system by analyzing this data the company can optimize their inventory levels and maximize the use of warehouse space. Additionally firms are more prepared for the demands and supplies of the market, especially during special circumstances such as a peak season on a particular month.

Disadvantages of Inventory Management System

The disadvantages of using the inventory management systems where there are

pro’s to suing a particular system will be automatically followed by some of the drawbacks or the cons of using the system .

- Cost

Cost can be a major disadvantage to suing the inventory management system. Many large companies can use the system but small business may find it difficult to afford the huge expenses of buying the system. Barcode readers and other hardware can compound this problem by adding even more cost to companies. The advantage of allowing multiple employees to perform inventory-management tasks is tempered by the cost of additional barcode readers.

- Complexity:

Inventory management system is not necessarily easier to learn , remember and use. A company’s management team must dedicate a certain amount of time to learning the new system, including both software and hardware, in order to implement for usage .Most inventory management software includes training manuals and other information available to users. Despite its apparent complexity, inventory management software offers a degree of stability to companies.

- Risk of fraud

Any computerized system carries the risk of intrusion, and with a computerized inventory management system comes the risk of fraud as well. A dishonest vendor could hack the system to receive payment for products never delivered, or a dishonest employee could redirect checks to themselves.

- Accuracy Issues

A computerized system alone does not ensure accuracy, and the inventory data is only as good as the data entry that created it. Companies that plan to use a computerized inventory management system need to have a system in place to validate their data and check the numbers reported by the system. A select hand count or targeted audit may be necessary to ensure the integrity of the system.

Similar systems

A comparative study

Vendor management systems

This system is a new trend for inventory management system. With this system the distributors can control inventory management for customers .The reports are calculated on daily basis and are transferred from the customer to the vendor. The data gathered from these reports lets the vendor knows when to recalculate the stock of the customers merchandise. This method significantly reduces the load of paper work /the cost and the labor .There are few drawbacks of using this method which is this will be difficult for the distributor/suppliers to keep up with demand of the product that is popular and is demanded by the customers from all around the world. Companies believe that the money saved in time and labor is worth the risks involved.

Traker systems

Traker system is an inventory management system allowing you to control your inventory with this software management system the you can you can track and control purchasing, invoicing, product recalls, shipping and receiving, ordering and all other aspects of inventory management. The software comes with full system of reports allowing you to have the status of your inventory available at your fingertips. Some of the forms available with Traker Systems include packing slips, invoices and inbound receipts. Analysis reports include analysis summary, allocation reports, products lists, inventory summary and inventory history. The operating system required to use Traker Systems is Windows 2000, Windows XP or Windows Vista.

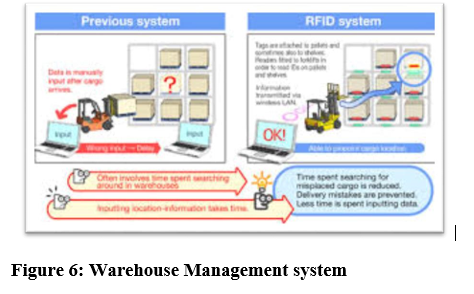

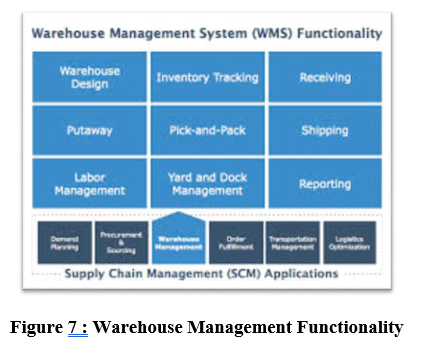

Warehouse management systems:

WMS (warehouse management system ) is a software application that supports day to day operations in the warehouse of company. The system enables centralized management of tasks such as tracking inventory levels and stock locations .WMS systems may be standalone systems or integrated with the ERP system.

Warehouse management system used previously could only store the data of stock locations .the current systems are so complex and data intensive that they require a dedicated staff to operate the system. High end system may include routing and tracking technologies such as RFID and voice recognition.

It does not matter how complex the system but the goal remains the same that to provide the management for information that it needs to move efficiently and control the movement of the materials within warehouse.

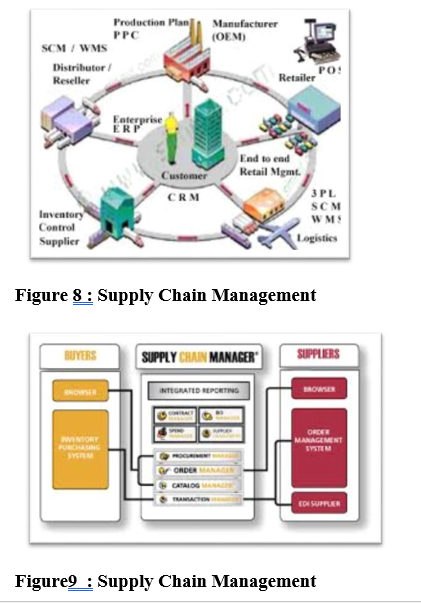

Supply chain management systems:

Is the active management of supply chain activities that maximizes customer value and achieves a sustainable competitive advantage .Supply chain activities covers everything from product development ,pricing ,logistics to the information system that is needed to coordinate these activities.

The organizations that make up the supply chain are “linked” together through physical flows and the information flows. Physical flows involve the transformation, movement, and storage of goods and materials. They are the most visible component of the supply chain. But is equally important as the information flows. Information flows allow the various supply chain partners to coordinate their long-term plans, and to control the day-to-day flow of goods and material up and down the supply chain.

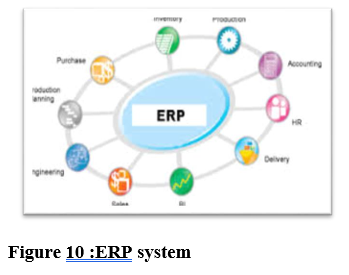

ERP (enterprise resource planning) systems :Is business management software that can be best describe as usually a suite of integrated applications which the company can use to store and manage data from every stage of business, including:

- Product planning, cost and development.

- Marketing and sales.

- Inventory management.

- Shipping and payment

ERP provides an integrated real-time view of core business processes, using common databases maintained by a database management system. ERP systems track business resources including cash, raw materials, production capacity and the status of business commitments: orders, purchase orders, and payroll. The applications that make up the system share data across the various departments (manufacturing, purchasing, sales, accounting, etc.) that entered the data. ERP facilitates information flow between all business functions, and manages connections to outside stakeholders.

Organizations consider the ERP system a vital organizational tool because it integrates varied organizational systems and facilitates error-free transactions and production. However, ERP system development is different from traditional systems development. ERP systems run on a variety of computer hardware and network configurations, typically using a database as an information repository.

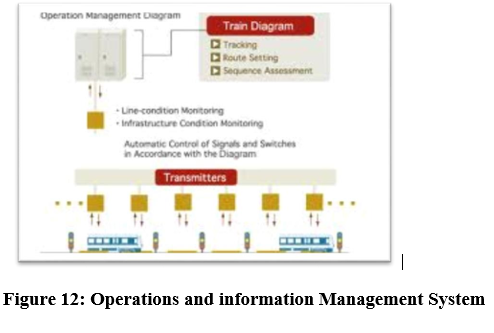

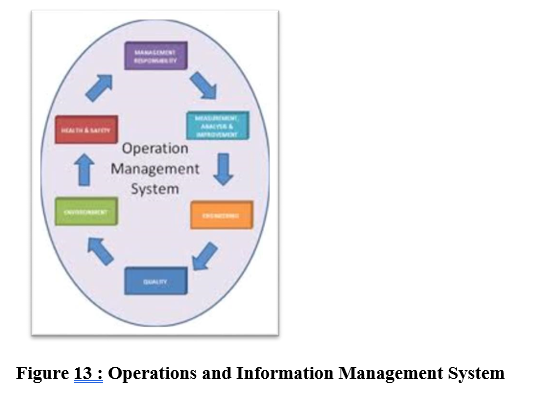

Operations management system:

Operations Management Systems (OMS) is an integrated collection of technologies that provides a two-way communication between the operating data generated on the shop floor and the software systems used by plant management to monitor the performance of one or multiple facilities.

Similar Softwares

Inflow software helps to organize and inventory system to track and control the stock with the help of executive dashboard helps to generate nice reports as the end result.

ProActive Inventory Manager by Accuware

Is a Web based Inventory Management solution. Can be customized to your unique work flows. Hosted on ProActive servers or can be hosted on your server. Option to use barcodes and Mobile computing. . Built on Microsoft ASP.net and Microsoft SQL server database Data available for clients to use Adhoc reporting. Low cost Standard version, or full blown Enterprise version.

Extensive set of versions for many Vertical industries.

Pos Maid Software

Pos Maid is free software for inventory management and control which is very helpful in merchandise retail sale like in provision store, super market store, electronics goods store etc. POS stands for Point of Sale. This program has many good features like you can easily fill in your inventory and has complete control over it; customer and employee management, financial report generation, account management, low stock alerts etc. This software is recommended for small business stores.

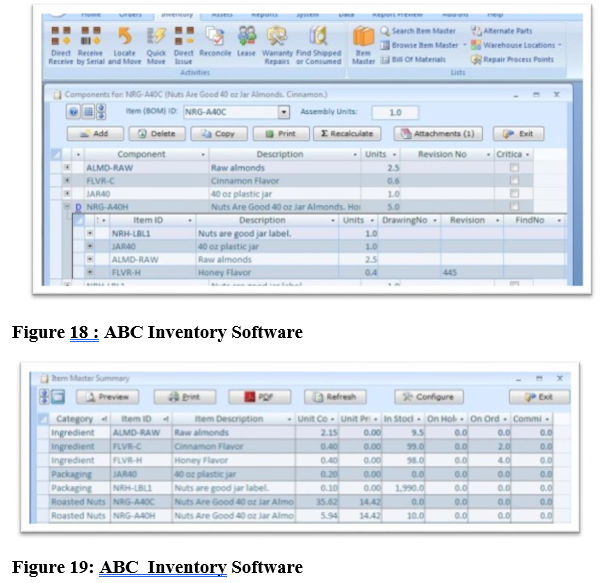

ABC Inventory Software:

ABC Inventory Software is a freeware inventory management application which should be an absolute choice for small and middle level business groups because it works like a professional. This program is jam packed with multiple features like purchase order management, complete inventory track along with barcode, sale and shipping order management, scheduling warehouse appointments, automatic stock report generation, sale quotations, unlimited database record, mailing labels and so on.

BS1 Enterprise Accounting Free Edition

BS1 Enterprise Accounting Free Edition is a freeware program for inventory control and management which is useful for small business section. This program has a very simple interface with very easy to use design. It has different department like accounting, distribution and manufacturing department which have further sub terms like sales orders, purchase orders, accounts payable, accounts receivable general ledger, inventory and much more.

Chronos eStock Card Inventory Software

Chronos e Stock Card Inventory software is a freeware inventory management application which keeps the complete track of your sales, purchase and warehouse inventory. It supports barcode system. Its features include detail inventory tracking, customizable interface, email alerts, complete inventory management, stock transfer, report generation, multi- currency conversion and many more.

Conclusion

This report clearly shows the introduction to the system with a detailed description of the advantages and disadvantages of the system and also presents a detailed comparative study of the similar systems and the similar softwares that are used to develop inventory management system applications in business settings.

Leave A Comment

You must be logged in to post a comment.